Discover a Vast Array of Aftermarket Construction Parts for Optimal Performance and Cost Savings

Wiki Article

Increase Efficiency With Aftermarket Components: an Overview for Heavy Machinery Owners

Benefits of Aftermarket Parts

Proprietors of heavy machinery can enjoy countless advantages by choosing for aftermarket components over initial devices producer (OEM) parts. Aftermarket components are commonly a lot more budget friendly than OEM parts, permitting equipment owners to reduce upkeep and repair service expenses without compromising on quality.Given that aftermarket producers specialize in producing details components, equipment proprietors have access to a wider array of options to match their requirements. Aftermarket components are recognized for their quality and dependability, with several meeting or surpassing OEM criteria.

Lastly, selecting aftermarket components can also result in faster repair services and lowered downtime. With simpler schedule and quick shipping choices, equipment proprietors can obtain their tools up and running again quickly, decreasing disruptions to their operations.

Choosing the Right Aftermarket Parts

When thinking about aftermarket components for hefty machinery, it is important to focus on compatibility and top quality to guarantee ideal efficiency and longevity of the equipment. Selecting the best aftermarket parts can be an important choice for hefty equipment owners as it directly affects the performance and integrity of their tools.

Secondly, quality ought to never be compromised when choosing aftermarket parts (aftermarket construction parts). Selecting high-quality components ensures durability, dependability, and overall performance of the machinery. It is suggested to resource aftermarket parts from respectable suppliers or suppliers understood for their top quality standards

In addition, taking into consideration aspects such as guarantees, customer reviews, and compatibility with existing systems can better assist in making the appropriate selection. By prioritizing compatibility and quality when picking aftermarket parts, heavy equipment proprietors can improve the efficiency and long life of their devices.

Installation and Upkeep Tips

For efficient procedure and longevity of hefty machinery, appropriate installation and regular upkeep are critical. When mounting aftermarket parts, make sure that you meticulously comply with the supplier's directions to ensure optimal performance. It is important to utilize the proper tools and methods to stop any damages during the installment procedure. Regular maintenance is critical to keep your machinery running efficiently. Create an upkeep routine that consists of tasks such as inspecting liquid degrees, inspecting for deterioration, and cleaning elements (aftermarket construction parts). Without delay deal with any kind of concerns that arise to avoid additional damages and costly fixings. Additionally, consider purchasing training for your maintenance personnel to guarantee they look at more info have the essential abilities to recognize and deal with prospective issues. By focusing on installment and upkeep treatments, you can make the most of the effectiveness and life-span of your hefty equipment, inevitably conserving money and time in the lengthy run.

Cost-Effectiveness of Aftermarket Parts

Appropriate installment and normal maintenance are foundational elements for hefty equipment proprietors intending to assess the cost-effectiveness of aftermarket parts for their tools. While initial devices manufacturer (OEM) parts are recognized for their top quality, aftermarket parts use an even more cost-effective remedy without compromising performance. By carefully evaluating the high quality and compatibility of aftermarket parts with their equipment, owners can strike an equilibrium between cost-effectiveness and performance, eventually optimizing the efficiency and durability of their heavy devices.Taking Full Advantage Of Effectiveness With Aftermarket Upgrades

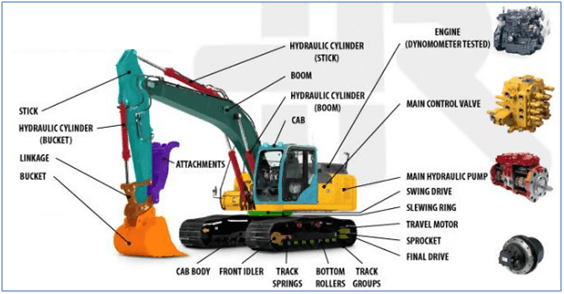

To boost operational performance and performance, heavy equipment owners can you can try these out properly take full advantage of performance through tactical application of aftermarket upgrades. Aftermarket upgrades offer the chance to tailor heavy equipment to details operational demands, leading to boosted performance and output. Upgrading elements such as engines, transmissions, hydraulic systems, and tracks can considerably enhance the overall efficiency of the machinery.

Routinely assessing the efficiency of heavy machinery and recognizing areas where aftermarket upgrades can be useful is essential for taking full advantage of efficiency. By investing in top quality aftermarket components and upgrades, machinery owners can accomplish greater degrees of effectiveness, ultimately leading to set you back savings and improved functional end results.

Final Thought

In verdict, aftermarket components offer many advantages for heavy equipment proprietors, including cost-effectiveness, boosted effectiveness, and customization options. By choosing the ideal aftermarket parts, complying with correct installation and maintenance procedures, and taking full advantage of upgrades, hefty machinery proprietors can improve their tools's efficiency and long life. Buying aftermarket components can ultimately cause boosted performance and lowered downtime, making it a rewarding factor to consider for proprietors aiming to maximize their equipment procedures.Owners of heavy machinery can delight in various benefits by opting for aftermarket components over initial devices maker (OEM) parts. Aftermarket parts are typically more cost effective than OEM components, enabling machinery proprietors to minimize maintenance and repair prices without endangering on high quality. By meticulously reviewing the high quality and compatibility of aftermarket parts with their equipment, proprietors can strike a balance you can look here between cost-effectiveness and performance, inevitably optimizing the effectiveness and longevity of their hefty devices.

In conclusion, aftermarket components provide numerous advantages for heavy equipment owners, including cost-effectiveness, boosted efficiency, and modification options. By picking the best aftermarket components, complying with proper setup and maintenance treatments, and making the most of upgrades, hefty machinery proprietors can increase their tools's performance and durability.

Report this wiki page